VMC850B CNC Milling makina, ofukula makina pakati

Zogulitsa Zamalonda

1.Malangizo onse

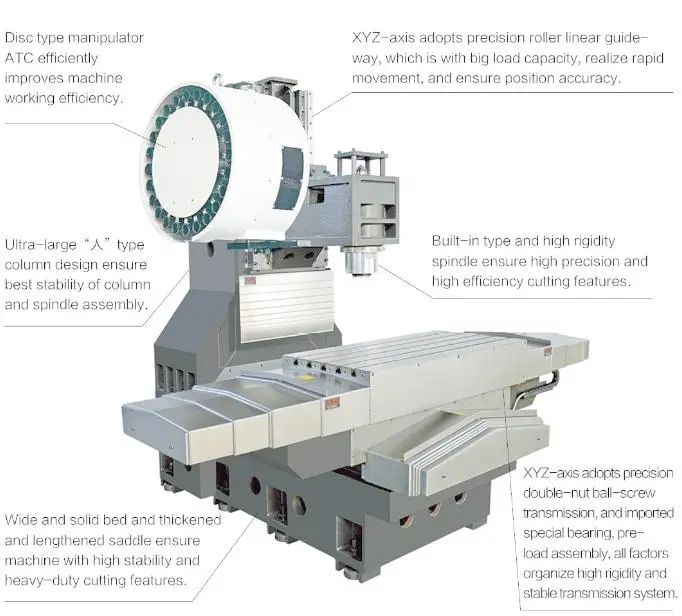

Makinawa adapangidwa ndi mawonekedwe a chimango choyima. Mzerewu umayikidwa pamakina, bokosi la spindle limayenda pamzere womwe umapanga Z axis motion, slide pamakina omwe amapanga Y axis motion, Worktable slide pa chishalo kupanga X axis motion. Nkhwangwa zitatu zonse ndi njira yolunjika yothamanga kwambiri komanso yolondola kwambiri. Timagwiritsa ntchito chitsulo chamtengo wapatali cha imvi pamakina, mzati, chishalo, chogwirira ntchito, bokosi la spindle chokhala ndi ukadaulo wa mchenga wa utomoni komanso chithandizo cha ukalamba ka 2 kuti tithetse kupsinjika kotsalira kwazinthu. Zigawo zonsezi zimakongoletsedwa ndi pulogalamu ya SolidWorks, yomwe imapangitsa kusasunthika komanso kukhazikika osati pazigawo izi komanso makina. Komanso idzaletsa mapindikidwe ndi kugwedezeka komwe kumachitika chifukwa cha kudula. Zofunikira zonse zimatumizidwa kuchokera ku mtundu wotchuka padziko lonse lapansi kuti makinawo akhale okhazikika komanso olimba. Makinawa amatha kukwaniritsa mphero, kubowola, kubwezeretsanso, kutayitsa, kukonzanso, kugogoda ndipo nthawi zambiri amagwiritsidwa ntchito ngati Asilikali, migodi, magalimoto, nkhungu, zida ndi mafakitale ena opangira makina. Itha kugwiritsidwa ntchito pamitundu yonse yolondola kwambiri komanso zitsanzo zambiri zamachitidwe. Ndi yabwino kwa ang'onoang'ono ndi apakatikati, kupanga mitundu yambiri, komanso imatha kuyika pamzere wopanga zokha.

2.Three nkhwangwa dongosolo

Nkhwangwa zitatu zonse ndi njira yolunjika komanso yokhala ndi mawonekedwe akulu okhazikika bwino. Ma motors a 3 nkhwangwa amalumikizidwa mwachindunji ndi zomangira zolondola kwambiri za mpira popanda kupanikizana kosinthika. Mpira uliwonse wononga nkhwangwa 3 kuchokera kunja kuchokera kulondola ngodya yolumikizidwa ya mpira sikona ndi akatswiri amafananiza, komanso tidzakonza zomangira zomangira mpira kuti zikhale zolondola kwambiri komanso zolondola. Pankhani ya kulephera kwamagetsi, brake yamoto imatha kugwiridwa ndi brake kuti isasunthike, zomwe zimathandizira kuteteza chitetezo.

3.Spindle unit

Spindle imapangidwa ndi akatswiri opanga kuti atsimikizire kulondola komanso kusasunthika. Spindle yonyamula ndi yochokera padziko lonse lapansi yodziwika bwino kwambiri, ndipo imasonkhanitsidwa pa kutentha kosalekeza komanso kopanda fumbi. Pambuyo pake, ma spindles onse amayesa kuchuluka kwamphamvu kuti atsimikizire kutalika kwa moyo ndi kudalirika. Ili ndi dongosolo lodzitchinjiriza lopanda kuthamanga kwa mpweya, ndikuwomba mpweya wocheperako mumlengalenga wamkati ndikupanga wosanjikiza woteteza mpweya kuteteza fumbi, kuziziritsa. spindle. Pa chikhalidwe ichi, chotchingira chopota chimagwira ntchito popanda kuipitsidwa ndi chilengedwe, chomwe chidzateteza gawo la spindle komanso moyo wautali wautali. Kuthamanga kwa spindle sikungakhale kosinthika mkati mwa liwiro la spindle, lomwe limayendetsedwa ndi injini yamkati yamkati kuti ikhale ndi ntchito ya spindle ndi kugogoda kolimba.

4.Tool kusintha dongosolo

The muyezo chida magazini mphamvu ya makina awa ndi 24T ndipo anasonkhana pa ndime mbali. Ikasintha chida, chida choyendetsa ndi kuyikidwa ndi makina oyendetsa makina oyendetsa makina, spindle ikafika pomwe chida chikusintha, ATC ikwaniritsa kusintha kwa chida ndikutumiza chida. ATC imapanga makina opangira makamera ndipo imapangitsa kuti ikhale yolimba kwambiri, ndiye kuti imatha kuthamanga kwambiri, zomwe zimakhala bwino kuti zisinthe mwachangu komanso molondola.

5.Coolant dongosolo

Makinawa ali ndi pampu yoziziritsira yoyenda molunjika komanso thanki yayikulu yamadzi. Liwiro la mpope woziziritsa ndi 2m³/h kuonetsetsa kuti kuziziritsa kokwanira kobwezeretsanso. Pamphepete mwa bokosi la spindle pali phokoso lozizirira, lomwe limapangitsa kuti mpweya ukhale wozizirira komanso wozizirira madzi pa chida ndi zidutswa zogwirira ntchito. Okonzeka ndi mpweya mfuti kuyeretsa makina ndi ntchito zidutswa.

6.Pneumatic system

Pneumatic unit imatha kusefa zonyansa ndi chinyezi mugwero la gasi kuti zipewe kuwonongeka ndi kukokoloka kwa magawo amakina. Solenoid valve unit imayang'anira pulogalamuyo ndi PLC kuonetsetsa kuti ntchito ya spindle unclamping chida, spindle center kuwomba, spindle clamping chida ndi spindle air coolant zitha kupangidwa mwachangu komanso molondola. Nthawi iliyonse chida chosinthira spindle, mpweya wowoneka bwino umawomba kuchokera pakati pa spindle kuti utsuke bowo lamkati la spindle ndi shank ya chida chifukwa cholimba kwambiri kuphatikiza ndi spindle ndi chida. Idzakulitsa nthawi ya moyo wa spindle.

7.Kuteteza makina

Timagwiritsa ntchito chishango chachitetezo chokhazikika pamakina, chomwe sichingangoteteza kuphulika koziziritsa komanso chitetezo. Kanjira kalikonse kamakhala ndi chishango choteteza chotchinga choziziritsira komanso chodulira mkati ndikuchepetsa kuvula ndi kukokoloka kwa njanji ndi zomangira za mpira.

8.Lubrication system

Guideway ndi wononga mpira zili ndi makina opaka mafuta apakati komanso cholekanitsa mafuta a volumetric mu Node Iliyonse, yomwe imatha kupereka mafuta pamlingo wokhazikika komanso nthawi kuti zitsimikizire kuti nkhope ya slide iliyonse yapaka mafuta komanso yocheperako. Idzawongolera kulondola komanso kutalika kwa moyo wa screw screw ndi kalozera.

9.Chip conveyor dongosolo

Timapereka chipangizo chojambulira chip chokhazikika chomwe chimagwira ntchito mosavuta. Komanso mutha kusankha screw type chip conveyor kapena hinge mtundu.

| Kanthu | Chigawo | Chithunzi cha VMC640L | Chithunzi cha VMC640LH | Chithunzi cha VMC850L | Chithunzi cha VMC1000L |

| Ntchito | |||||

| Ntchito kukula | mm | 400 × 900 | 400 × 900 | 500 × 1000 | 500 × 1200 |

| T-kagawo (N×W×D) | mm | 3 × 18 × 100 | 3 × 18 × 100 | 5 × 18 × 100 | 5 × 18 × 100 |

| Maulendo | |||||

| Ulendo wa X axis | mm | 640 | 640 | 850 | 1000 |

| Ulendo wa Y axis | mm | 400 | 400 | 500 | 500 |

| Ulendo wa Z axis | mm | 400 | 500 | 600 | 600 |

| Makina osiyanasiyana | |||||

| Mtunda wochokera pakati pa spindle kupita kutsogolo | mm | 440 | 476 | 572 | 572 |

| Mtunda kuchokera kumapeto kwa spindle kupita ku tebulo la ntchito | mm | 120-520 | 120-620 | 120-720 | 120-720 |

| Kukula kwa makina | |||||

| L×W×H | mm | 2200×2100×2500 | 2200×2100×2550 | 2540×2320×2780 | 3080×2320×2780 |

| Kulemera kwa makina | |||||

| Max. kunyamula katundu wa worktable | kg | 350 | 350 | 500 | 600 |

| Kulemera kwa makina | kg | 3900 pa | 4100 | 5200 | 5600 |

| Spindle | |||||

| Spindle hole taper | Mtengo wa BT40 | Mtengo wa BT40 | Mtengo wa BT40 | Mtengo wa BT40 | |

| Mphamvu ya spindle | kw | 5.5 | 5.5 | 7.5/11 | 7.5/11 |

| Max. liwiro la spindle | rpm pa | 8000/10000 | 8000/10000 | 8000/10000 | 8000/10000 |

| Kudyetsa (kuyendetsa mwachindunji) | |||||

| Max. liwiro la chakudya | Mm/mphindi | 10000 | 12000 | 12000 | 12000 |

| Kuthamanga kwachangu (X/Y/Z) | m/mphindi | 20/20/10 | 30/30/24 | 32/32/30 | 32/32/30 |

| Mpira wononga (diameter + lead) | |||||

| X axis mpira screw | 3210 | 3212 | 4016 | 4016 | |

| Y axis mpira screw | 3210 | 3212 | 4016 | 4016 | |

| Z axis mpira screw | 3210 | 4012 | 4016 | 4016 | |

| Magazini ya Chida | |||||

| Chida magazini mphamvu | T | 16 | 16 | 24 | 24 |

| Chida chosintha nthawi | s | 2.5 | 2.5 | 2.5 | 2.5 |

| Positioning kulondola (National standard) | |||||

| Kulondola kwa malo (X/Y/Z) | mm | 0.008 | 0.008 | 0.008 | 0.008 |

| Kuyikanso kolondola (X/Y/Z) | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| AYI. | Dzina | Mtundu |

| 1 | CNC ndondomeko | Zithunzi za 808D SYSTEM |

| 2 | Makina akulu | Seti yathunthu ya Nokia drive kuphatikiza servo mota |

| 3 | X/Y/Z axis motor, driver | Seimens |

| 4 | Mpira | Hiwin kapena PMI (Taiwan) |

| 5 | Mpira wonyamula | NSK (Japan) |

| 6 | Linear guides | Hiwin kapena PMI (Taiwan) |

| 7 | Spindle motor | POSA/ROYAL (Taiwan) |

| 8 | Chotenthetsera kutentha | Taipin/Tongfei (Joint-venture) |

| 9 | Mafuta dongosolo zigawo zikuluzikulu | Proton (Zogwirizana) |

| 10 | Pneumatic system zigawo zikuluzikulu | AirTAC (Taiwan) |

| 11 | Zigawo zazikulu za dongosolo lamagetsi | Schneider (France) |

| 12 | Pompo madzi | China |